UAE : Electric heating single facer line

QUOTATION LIST:

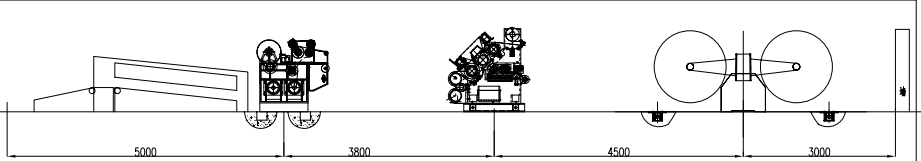

Flowchart:

Each machine details: 01. RS200 Electric Mill Roll Stand

►Structure and Features: 1.Symmetrical structure,can carry two kraft paper at one time,which can work without brake. 2. Clamping , moving right-left, arms up-down and paper roll rotation is by electric drive. 3.Toothed chuck, Pneumatic disc-brakes ►Spec of Stand: 1. Reel Stand driven by electrical 2. Kraft paper range: Max. Width:1600mm Min.:800mmmm Max Weight:2000Kg(One side)

►Spec of Electric Motor: 1. Reel Paper Nipping Motor Power: 0.55kw*4pcs 2. Lifting Motor Working Power: 1.5KW ►Mainly purchased parts, raw materials and origin:

02. SF280-1600 Electric Heating Fingerless Single Facer ►Glue Rollers:

►Corrugated Rollers:

►Press Rollers:

►Preheater Rollers:

►Common Spec:

►Common Spec: 1. Effective width:1600mm 2. Operation direction:left or right(determined in accordance with customer plant) 3. Design Speed:80m/min Working Speed: 60m/min 5. Temperature: 160—200℃ 6. Air source:0.4—0.9Mpa 7. pressure:0.8—1.3Mpa 8. Corrugated flute:(UV type or UVV type) ►Spec of Motor: 1. Main drive motor:7.5KW Rated voltage:380V 50Hz Continuous (S1) working standard 2. Suction motor:7.5KW Rated voltage:380V 50Hz Continuous (S1) working standard ►Mainly purchased parts, raw materials and origin:

03. SCT-NC100-1600 Computer Heavy duty Cutter

►Technical parameter: Working width: 1600mm Design speed: 100m/min Working speed: 80m/min Cutting length: MAX 9999mm MIN 260mm Cutting precision: ±1mm (constant speed) Wallboard thickness: 100 mm(heavy type) Electric power: 380V 50Hz Main motor power: 6 kw Overall dimension: 2500mm× 2400mm×1550mm ►Structure Features: Wallboard and base material: iron cast Transmission system lubrication: adopts oil immersing lubrication, insure transmission precision Driving unit: double frequency motor control system, computer storage order, touch screen change order, input the order. Knife pedestal material is iron cast, knife material is high speed tool steel, Rubber roll automatic adjusting the gap by pneumatic cylinder Gear: nodular cast iron, low noise, transmission steady Equipped with 3 sets slitting blade. Blade outside with protection cover. ►Mainly purchased parts, raw materials and origin:

04. SST-1600 Auto single face corrugated board stacker

►Technical parameter Automatic stacking, automatic counting; Stacking length is: 500-1500mm Stacking width: 1600mm Stacking piles: 4piles. Staking height: 0-200mm ►Mainly purchased parts, raw materials and origin:

Article classification:

corrugator

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||